- About Ajou

- Admission

- Academics

- Research

-

International

International

- Campus Life

-

News and Event

News and Event

- AUT

Major Research Result

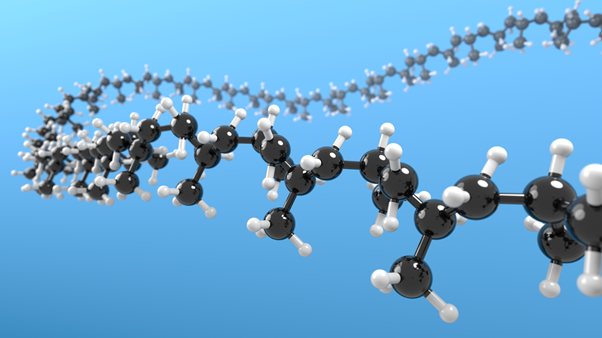

NEW Pollutant to Polymer: Polymerizing Propylene Oxide and Carbon Dioxide Using Zinc-Gallate Catalyst

- 2024-09-23

- 703

Advancing towards carbon neutrality, researchers develop a highly efficient zinc-gallate catalyst for propylene oxide and carbon dioxide polymerization

Zinc-based polymerization catalysts can help utilize carbon dioxide (CO2) as a carbon source for polymerization and production of sustainable plastics with various applications such as adhesives and feedstock for polyurethane. For advancing the production of eco-friendly CO2-derived polymers, a team of researchers demonstrated a simple method of synthesizing a highly effective and selective catalyst Zinc-gallate. The nanometer-scale layered structures of the catalyst showed high performance in propylene oxide and carbon dioxide polymerization. These findings herald a move towards a carbon neutral future.

Scientists developed an innovative, highly active, and selective ultrathin zinc-gallate catalyst that can facilitate the copolymerization of propylene oxide and carbon dioxide into a high molecular weight polymer.

Carbon dioxide (CO2) emissions from human activities are a major cause of climate change. Converting CO2 into useful products is a promising solution to help address this issue. One such strategy is utilizing CO2 for the polymerization of organic molecules to produce industrially useful products. In fact, significant efforts have been made for the development of effective catalysts for the development of such sustainable products from CO2.

A popular choice of material for speeding up CO2-aided polymerization reactions is zinc-based catalysts. The most potent zinc-based heterogeneous catalyst with a very high activity reported to date is the zinc glutarate (ZnGA) catalyst, used for the production of alternating polycarbonate from propylene oxide (PO) and CO2. However, the catalytic activity of ZnGA is insufficient for its commercial use. This necessitates improvements in the catalytic activity of zinc-based catalysts for commercial applications.

Now advancing research, a team of researchers from Ajou University, led by Professor Hye-Young Jang, addressed the existing catalytic limitations of ZnGA. In their study published in ACS Sustainable Chemistry & Engineering on February 26, 2024, they developed a new highly active and selective heterogeneous ultrathin zinc (Zn)-gallate for the copolymerization of PO and CO2 into high molecular weight polymer.

“This research aims to develop highly efficient catalysts for CO2 polymerization to produce eco-friendly CO2-derived plastics. Replacing traditional fossil fuel-based plastics with these novel materials can significantly reduce both the consumption of fossil fuels and limit further CO2 emissions,” said Prof. Jang highlighting the motivation behind this study.

The team used cost-effective zinc salts and gallic acid to synthesize a novel Zn-gallate catalyst and analyzed its morphology and catalytic mechanism. They attributed the nanometer-sized structures in the catalyst to its excellent catalytic activity, minimal monomer formation, and high carbonate linkage proportion. Comparative studies revealed that Zn-gallate outperformed many of its counterparts when catalyzing PO and CO2 polymerization.

Talking about these findings, Prof. Jang says, “The catalyst developed in this study demonstrates exceptional catalytic activity and economic viability. We believe that our approach will help pave the pathway towards carbon neutrality by the year 2050.”

In summary, the facile synthesis procedure and the reaction mechanisms reported in this study can significantly accelerate the development of high-performance Zn-based polymerization catalyst and their adoption in commercial applications.

Reference

Authors: | Yongmoon Yang1, Kihyuk Sung1, Jong Doo Lee2, Junho Ha1, Heeyoun Kim1, Jinsu Baek3, Jeong Hwa Seo4, Seung-Joo Kim4 Bun Yeoul Lee5 Seung Uk Son2, Byeong-Su Kim3, Yongsun Kim1, Ji-Yong Park1, and Hye-Young Jang1 |

Title of original paper: | Ultrathin Zn-Gallate Catalyst: A Remarkable Performer in CO2 and Propylene Oxide Polymerization |

Journal: | |

DOI: | |

Affiliations: | 1Department of Energy Systems Research, Ajou University, Korea 2Department of Chemistry, Sungkyunkwan University, Korea 3Department of Chemistry, Yonsei University, Korea 4Department of Chemistry, Ajou University, Korea 5Department of Molecular Science and Technology, Ajou University, Korea |

*Corresponding author’s email: hyjang2@ajou.ac.kr

About Ajou University

Founded in 1973, Ajou University has quickly grown to become one of the top universities in the Republic of Korea. With over 15,000 students and 50 research centers in diverse fields, Ajou University partakes in the largest national research and graduate education project funded by the Korean Ministry of Education. In line with its recently reformed vision, Ajou University’s goal is to change society by connecting minds and carrying out high-impact research to improve the welfare of people in and outside Korea.

Website: https://www.ajou.ac.kr/en/index.do

About Professor Hye-Young Jang

Dr. Hye-Young Jang is a Professor of Chemistry and Chair of the Department of Energy Systems Research at Ajou University. Before coming to Ajou University, she completed Postdoctoral training at MacMillan’s group (2021 Nobel Prize-winning group in Chemistry) at Caltech (2006). In 2005, Hye-Young Jang received her Doctor of Philosophy degree in Chemistry from The University of Texas at Austin under the supervision of Prof. Krische. Prof. Jang and her group are currently developing sustainable catalytic processes using renewable carbon resources such as CO2, plastic waste, and biomass.