-

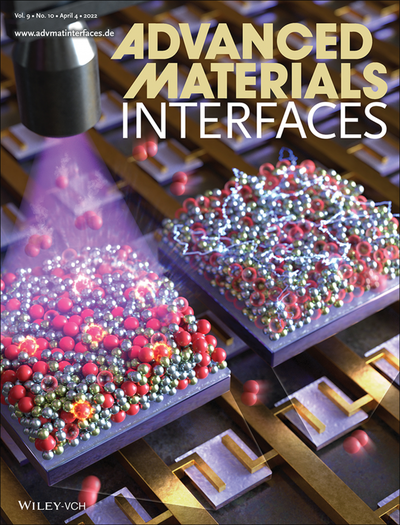

Researchers propose a novel technique for selectively and rapidly modulating the threshold voltage of indium–gallium–zinc oxide thin-film transistorsIndium–gallium–zinc oxide (IGZO) semiconductors are promising as active components in thin-film transistors owing to their favorable electrical and optical properties. However, uncontrolled oxygen vacancies in IGZO can degrade device performance through negative shifts in the transistor threshold voltage (Vth), which should ideally be close to zero. Now, researchers from Korea realize a rapid modulation of Vth using UV irradiation, opening doors to reliable oxide devices with high mobility and large-area transparency.Caption: Selective modulation of the threshold voltage (Vth) in indium–gallium–zinc oxide semiconductor-based thin-film transistors with UV/ozone treatment of the substrate. Amorphous indium–gallium–zinc oxide (IGZO) semiconductors are an essential component in the fabrication of next-generation unconventional electronic devices and have been considered as active components in thin-film transistors (TFTs), thanks to their electrical and optical performances. Moreover, they allow for high-throughput production via sol–gel process.In TFTs, an important scaling factor for device performance is the threshold voltage (Vth). Ideally, a Vth close to 0 V is desirable for accurate and stable operation. However, in IGZO-based TFTs, a major problem arises from uncontrolled oxygen vacancies in the IGZO layer, which results in negative shifts in Vth. This, in turn, leads to unstable and poor device performance. While several methods have been adopted for controlling these vacancies, it is still challenging to adjust Vth quickly at room temperature since controlling the vacancies require long processing times. To address these issues, a team of researchers from Korea has recently proposed a novel UV/ozone (UVO) treatment of the IGZO layer at room temperature that enables a rapid adjustment of Vth within 3 minutes. “The proposed technology for Vth modulation using UV light can be selectively operated within the substrate area. As a result, we were able to demonstrate IGZO semiconductors with different Vth values by controlling the exposed area,” explains Prof. Sungjun Park from Ajou University, who led the study. In their work published in the journal of Advanced Materials Interfaces, the team used a sol–gel process to fabricate large-area IGZO semiconductors in a cost-effective manner. Then, using the UVO treatment, they showed that they could preserve the Vth close to 0 V under gate bias stress. To understand the mechanism underlying the UVO-based modulation, the team examined the electrical and physicochemical properties of the IGZO TFTs with and without the UVO treatment using transmission line method and X-ray photoelectron spectroscopy. The analysis revealed that the UVO treatment led to both a rapid decline in oxygen vacancies as well as the formation of strong bonding in the IGZO channel without any change in the contact resistance. This, in turn, allowed for a fast Vth modulation with stable device operation.“The Vth modulation by UV irradiation points to the selective performance control of metal oxide sol–gel devices and circuits and highlights their potential as a substitute for silicon semiconductor, ” says Prof. Park. “The performance variation of the IGZO TFTs through UVO irradiation can be used in the latest technologies that require high mobility and transparency, such as displays and optical communication,” he concludes. Indeed, IGZO semiconductors may come to dominate the semiconductor industry soon! ReferenceAuthors:Wonsik Kim1, Won-June Lee2, Taehyun Kwak1, Seokhyeon Baek1, Seung-Hoon Lee3, and Sungjun Park1,*Title of original paper:Influence of UV/Ozone Treatment on Threshold Voltage Modulation in Sol–Gel IGZO Thin-Film TransistorsJournal:Advanced Materials InterfacesDOI:10.1002/admi.202200032Affiliations:1Department of Electrical and Computer Engineering, Ajou University2School of Materials Science and Engineering, Gwangju Institute of Science and Technology3Division of Advanced Materials, Korea Research Institute of Chemical Technology (KRICT) *Corresponding author’s email: sj0223park@ajou.ac.kr About Ajou UniversityFounded in 1973, Ajou University has quickly grown to become one of the top universities in the Republic of Korea. With over 15,000 students and 50 research centers in diverse fields, Ajou University partakes in the largest national research and graduate education project funded by the Korean Ministry of Education. In line with its recently reformed vision, Ajou University’s goal is to change society by connecting minds and carrying out high-impact research to improve the welfare of people in and outside Korea. Website: https://www.ajou.ac.kr/en/index.do About the authorDr. Sungjun Park is an Assistant Professor at the Department of Electrical and Computer Engineering at Ajou University, Korea since 2020. His group studies flexible and stretchable high-performance electronic devices for wearable and bio-medical applications. Before coming to Ajou University, he received his PhD from the School of Materials Science and Engineering at Gwangju Institute of Science and Technology in Korea in 2016. Thereafter, he did his postdoctoral training at RIKEN and remained a visiting researcher at the University of Tokyo, Japan, from 2016 to 2018. Thereafter, he worked as a Senior Researcher in Samsung Advanced Institute of Technology (SAIT) in Korea from 2018 to 2020.

-

50

- 작성자국제협력팀

- 작성일2022-11-15

- 7164

- 동영상동영상

-

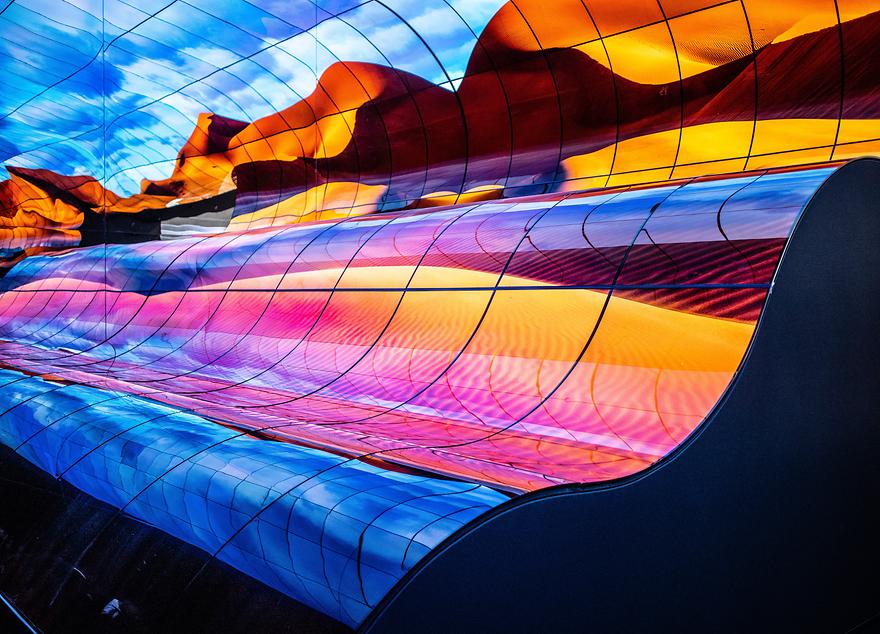

Researchers develop an alternative to inkjet printing for enhanced intensity and perfect color conversion in organic LED displaysExisting blue organic light emitting diode (BOLED) displays use inkjet printing-based color filters for color conversion, resulting in a trade-off between perfect conversion and brightness. To tackle this, researchers from Korea have now developed luminescent films that are extremely thin compared to inkjet printing, can completely convert colors, and enhance light intensity. The deposited films could potentially be applied to quantum dot-enhanced BOLED displays soon. Credit: Grzegorz Czapski from Shutterstock.Caption: A technique developed by researchers from Korea, called ultrasonic-assisted aerosol deposition, for the direct co-deposition of perovskite quantum dots and metal oxides facilitates perfect color conversion and enhances the luminance of blue OLED displays.In recent times, organic light emitting diodes (OLEDs) have revolutionized the flat-panel display industry. Additionally, with the advent of quantum dot (QD)-enhanced LCDs, it is now possible to achieve a wide range of realistic color experience owing to their narrower emission bandwidth. But, the dependence of these technologies on color filters to produce color subpixels limits their utilization in large-area panel displays. This challenge persists even with the novel QD-OLED hybrid system, which uses an inkjet printing process to print color conversion layers (CCLs). Besides being stringent, the inkjet printing process fails to achieve the optimal thickness and density for QDs and experiences the issue of blue light leakage, impeding the advancement of these display technologies. Now, a team of researchers from Korea report a novel film fabrication method that overcomes these limitations, facilitating perfect color conversion and enhanced light intensity. The study was led by Prof. Sang-Wook Kim of Ajou University, Korea and was published in the Chemical Engineering Journal. As Prof. Kim explains, “We utilized a technique called ‘ultrasonic-assisted aerosol deposition’ (UAD) [A1]to develop thin CCLs and simultaneously used lead halide perovskite nanocrystals as light-emitting material on CCLs, which demonstrated excellent color purity and high luminous efficiency levels.” To this end, the researchers prepared a blue OLED (BOLED) using ITO glass and deposited the synthesized perovskite quantum dot (PeQD) aerosol /metal oxide composite layers on it. The deposited films were a mere 3 μm thick, a quarter of the inkjet-printed films! The PeQD layers embedded with aluminum oxide and silica particles facilitated efficient blocking of blue light leakage. In addition, the metal oxides significantly increased the luminance intensity from the BOLED to the CCL. Further, the researchers demonstrated the compatibility of this novel technique with versatile patterning processes. They showed that UAD can be combined with a fine-metal shadow mask to produce a pattern of 30-μm diameter dots. Particularly, the direct writing method for creating PeQD array patterns provided the narrowest line patterns of about 13 μm. Elaborating the advantage of this method, Prof. Kim notes, “The proposed technique enables the formation of very dense films without the need for any complicated equipment, and requires relatively less throughput time compared to other deposition techniques.” This development can greatly simplify the color patterning process in LED displays, and help achieve high display resolutions, marking an advancement in display printing technology. Going ahead, the “color filter free” method is expected to find usage in QD-enabled displays, ultimately contributing to their application in ultra-large panel displays.ReferenceAuthors:Sunghoon Kim1, Seokwoo Kang2, Seungmin Baek3, Jinouk Song4, Na-Eun Mun1, Hyukmin Kwon2, Hyo-Geun Kwon3, Yong-Jin Pu5, Tae-Woo Lee6, Seunghyup Yoo4, Jong-Min Oh7, Jongwook Park2, Sang-Wook Kim3Title of original paper:Highly thin film with aerosol-deposited perovskite quantum dot/metal oxide composite for perfect color conversion and luminance enhancementJournal:Chemical Engineering JournalDOI:https://doi.org/10.1016/j.cej.2022.135991Affiliations:1 Department of Applied Chemistry Food Science and Technology, Dong-Eui University2 Integrated Engineering, Department of Chemical Engineering, Kyung Hee University3 Nanomaterials Laboratory, Department of Molecular Science and Technology, Ajou University4 School of Electrical Engineering, Korea Advanced Institute of Science and Technology (KAIST) 5 RIKEN Center for Emergent Matter Science (CEMS)6 Department of Materials Science and Engineering, Seoul National University7 Department of Electronic Materials Engineering, Kwangwoon University*Corresponding author’s email: swkim@ajou.ac.krAbout Ajou UniversityFounded in 1973, Ajou University has quickly grown to become one of the top universities in the Republic of Korea. With over 15,000 students and 50 research centers in diverse fields, Ajou University partakes in the largest national research and graduate education project funded by the Korean Ministry of Education. In line with its recently reformed vision, Ajou University’s goal is to change society by connecting minds and carrying out high-impact research to improve the welfare of people in and outside Korea. Website: https://www.ajou.ac.kr/en/index.do About the authorSang-Wook Kim is a Professor at the department of bioengineering and applied chemistry, Ajou University. He received his PhD in applied chemistry from the Seoul National University in 2002. Thereafter, he completed his postdoctoral training from the Bawendi lab at Massachusetts Institute of Technology, USA before joining Ajou University. His research mainly focuses on quantum dot synthesis and application. In the recent past, he has worked on perovskite quantum dots and their LED application. He has published about 150 papers on nanoscience.[A1]We have now added this abbreviation here since it has been used later in the press note.

-

48

- 작성자국제협력팀

- 작성일2022-11-15

- 7283

- 동영상동영상

-

Researchers use shape memory alloys to create compact, lightweight, and high power density actuators for wearable devicesWearable optical devices find use in several fields, ranging from gaming to medicine. To improve on the immersive visual experience current devices offer, researchers from South Korea have developed an all-new compliant amplified shape memory alloy actuator (CASA). Its elliptic configuration and compliant structure amplify actuation strain and retain power density. Moreover, the artificial muscle-like actuator is light and compact. The researchers also demonstrate CASA-based prototype augmented reality glasses and two-way communication 3D-touch gloves. Wearable technology is expected to utilize shape memory alloy-based actuators in the near futureImage source: ShutterstockWearable devices are a technology with gaming, medical, and communication applications. They require compact, lightweight, and high power density actuators—devices that move and control a mechanism—for smart operation. These criteria put a variety of design constraints from an engineering standpoint. Previous studies have considered using shape memory alloys (SMAs), amongst other materials, for actuators. However, they suffer from low energy efficiency and require additional heavy components.Recently, a team of researchers from South Korea, led by Prof. Je-Sung Koh of Ajou University, have developed a compliant amplified SMA actuator (CASA) for wearable devices. It employs a minimal strain-amplification mechanism to compensate for the existing shortcomings. The findings were published in Nature Communications on 18th July 2022. Prof. Koh explains the fundamentals of CASA: “The actuator has an optimized elliptic configuration and a compliant structure: that of an artificial muscle. It consists of an SMA wire and elastic beams that amplify actuation strain and minimize power density reduction. The actuator weighs only 0.22 grams but is powerful enough to throw 10 grams of weight. Moreover, it has a relatively high power density of 1.7 kW/kg and an actuation strain of 300% under 80 grams of external payload.”The researchers have integrated this actuator with a bistable parallelogram linear stage. It improves energy efficiency, making possible the development of compact devices. Prof. Koh’s team has utilized the artificial muscle actuator to demonstrate multi-focus augmented reality glasses and soft 3D-touch gloves. The prototype glasses are capable of image depth control to relieve visual fatigue. On the other hand, the haptic gloves generate high pressures to provide large skin-deformation sensations for the wearer. They can also detect external contact by utilizing the actuator as a resistance-type force sensor, establishing two-way communication. “The present research has demonstrated the practical use of smart materials in commercial wearable devices. CASA has distinguishing performance in terms of actuation strain, power density, weight, and form factor. I believe it can replace the commercially available motor-based actuators soon,” concludes Prof. Koh.ReferenceAuthors:Dongjin Kim1, Baekgyeom Kim1, Bongsu Shin2,3, Dongwook Shin1, Chang-Kun Lee2,3, Jae-Seung Chung2,3, Juwon Seo2,3, Yun-Tae Kim2,3, Geeyoung Sung2,3, Wontaek Seo2, Sunil Kim2, Sunghoon Hong2, Sungwoo Hwang2,4, Seungyong Han1, Daeshik Kang1, Hong-Seok Lee2,5 and Je-Sung Koh1Title of original paper:Actuating compact wearable augmented reality devices by multifunctional artificial muscleJournal:Nature Communications DOI:https://doi.org/10.1038/s41467-022-31893-1Affiliations:1Department of Mechanical Engineering, Ajou University, 206 Worldcup-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do 16499, Republic of Korea. 2Samsung Advanced Institute of Technology, Samsung Electronics, 130 Samsung-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do 16678, Republic of Korea3Samsung Electronics, 34, Seongchon-gil, Seocho-gu, Seoul 06765, Republic of Korea4Samsung SDS, 125, Olympic-ro, 35-gil, Songpa-gu, Seoul 05510, Republic of Korea5Department of Electrical and Computer Engineering, Seoul National University, 1, Gwanak-ro, Gwanak-gu, Seoul 08826, Republic of Korea*Corresponding author’s email: jskoh@ajou.ac.krAbout Ajou UniversityFounded in 1973, Ajou University has quickly grown to become one of the top universities in the Republic of Korea. With over 15,000 students and 50 research centers in diverse fields, Ajou University partakes in the largest national research and graduate education project funded by the Korean Ministry of Education. In line with its recently reformed vision, Ajou University’s goal is to change society by connecting minds and carrying out high-impact research to improve the welfare of people in and outside Korea. Website: https://www.ajou.ac.kr/en/index.doAbout the authorProf. Je-Sung Koh is an Associate Professor in Department of Mechanical Engineering at Ajou University, Republic of Korea. His research group is developing biologically inspired robotic technologies. These include abstracting principles of nature creatures and building a biologically inspired robot using smart materials. His research interests encompass design and fabrication with smart materials, robots based on foldable structure, and soft robotics for enabling human-robot interaction.

-

46

- 작성자국제협력팀

- 작성일2022-11-07

- 3958

- 동영상동영상

-

The unique heterostructure of the photoanode displays enhanced charge collection, providing valuable insights into the design of efficient fuel cellsOngoing climate change has made the development of new renewable energy sources the need of the hour. The hydrogen production through water-splitting reactions is one of the most promising options, but the commercial viability of current technologies is limited. Recently, researchers developed a novel, dual textured heterostructure that provides key insights into the design of efficient water-splitting electrodes. The development of an efficient, high-performance photoanode for water-splitting reactions is the major technological bottleneck to the production of hydrogen through photoelectrochemical water-splitting cells. This research presents a novel, unique heterostructure design for photoanodes that displays enhanced performance.One of the most promising technologies to solve the dual problems of the energy crisis and climate change is photoelectrochemical (PEC) water-splitting. PEC water-splitting is the process through which water molecules are split into hydrogen and oxygen through a light-catalyzed reaction in an electric cell. A key component of these cells is the photoanode, the light-sensitive negative electrode. The design of an efficient, high-performance photoanode is one of the technological bottlenecks to the commercialization of PEC cells.Heterostructure engineering—the combination and assembly of dissimilar materials into a single substrate—is a common approach to improving the design and subsequent performance of photoanodes. But research on the topic has, thus far, been limited to core/shell and planar heterostructure designs. Recently, researchers—led by Prof. In Sun Cho of Ajou University, Republic of Korea—have developed a novel heterostructure design with the potential to overcome the performance limiting factors of photoanodes. “Our novel design is a dual textured heterostructure that synergistically combines heterojunction (the interface between two dissimilar semiconductors) and texture/facet (crystallographic orientation and exposure of material planes) engineering,” explains Prof. Cho. Their work has been published in Chemical Engineering Journal.In this study, the research team first grew Sb:SnO2, or antimony-tin oxide (ATO), nanorods on fluorine-enriched tin oxide substrate. Next, they spin-coated a layer of BiVO4, or bismuth-vanadium oxide (BVO), on the nanorods, followed by a second hydrothermal growth to synthesize the heterostructure. The unique heterostructure exhibited a dual texture with intimate heterojunctions. It also has two different facets. Furthermore, it displayed enhanced charge collection and quadruple photocurrent density compared to its single-textured counterpart. Discussing the future implications of the work, Prof. Cho says, “The research presents new ideas for heterojunction design that can be widely applied to energy production and storage technology devices, like fuel cells.”The optimized synthesis method presented here can also be used to control morphology during the synthesis of a variety of other oxides, thereby extending its applications to energy fields beyond PEC water-splitting.ReferenceAuthors:Yoo Jae Jeong1,2, Sung Won Hwang1,2, Settasit Chaikasetsin3, Hyun Soo Han3, In Sun Cho1,2,*Title of original paper:Dual textured BiVO4/Sb:SnO2 heterostructure for enhanced photoelectrochemical water-splittingJournal:Chemical Engineering Journal DOI:10.1016/j.cej.2022.135183Affiliations:1Department of Materials Science & Engineering, Ajou University, Republic of Korea 2Department of Energy Systems Research, Ajou University, Republic of Korea3Department of Mechanical Engineering, Stanford University, United States *Corresponding author’s email: insuncho@ajou.ac.krAbout Ajou UniversityFounded in 1973, Ajou University has quickly grown to become one of the top universities in the Republic of Korea. With over 15,000 students and 50 research centers in diverse fields, Ajou University partakes in the largest national research and graduate education project funded by the Korean Ministry of Education. In line with its recently reformed vision, Ajou University’s goal is to change society by connecting minds and carrying out high-impact research to improve the welfare of people in and outside Korea. Website: https://www.ajou.ac.kr/en/index.doAbout the authorProf. In Sun Cho is an Associate Professor of Materials Science & Engineering at Ajou University, Republic of Korea. He received his PhD in Materials Science & Engineering from Seoul National University. Before coming to Ajou University, he completed his postdoctoral training at the Xiaolin Zheng lab at Stanford University. His group develops high-performance energy and catalysis devices. They are also involved in research on new and inexpensive nanomaterials with high functionalities.

-

44

- 작성자국제협력팀

- 작성일2022-10-25

- 4909

- 동영상동영상

-

A breakthrough linkage-driven robotic hand can grasp objects and manipulate everyday tools with superior efficiencyHumanoid robotic hands often have low dexterity and degrees of freedom, requiring additional attachments for performance enhancement, which makes their integration with robotic arms difficult and limits their applications. Now, researchers from Korea have developed a high-dexterity anthropomorphic robotic hand using a linkage-driven mechanism, which can be mounted on a commercial robot arm to perform complex tasks with dexterity and strength. A team of scientists developed a linkage-driven anthropomorphic robotic hand with high dexterity and tactile sensing that can perform everyday tasks and manipulate tools. Image source: Timusu, PixabayAlmost a quarter of the 206 bones in our body are in our hands. These 54 bones, and a complex architecture of muscles, facilitate the dexterity and sophisticated functioning of our hands. Translating these onto a humanoid robotic arm remains one of the unresolved quandaries of robotics. Currently, robotic hands can perform dexterous grasping motions with their high degree of freedom (DOF). However, these typically come with an attached forearm, which holds all the actuators (devices that move the robotic joints) required for motion. This large forearm prevents integration with already existing humanoid robot arms, thereby limiting application.Now, a team of researchers, led by Dr. Uikyum Kim from Ajou University, Korea, have developed a novel integrated linkage-driven dexterous anthropomorphic (ILDA) robotic hand, whose design solves some of these challenges and was recently published in a Nature Communications paper. Prof. Kim explains, “Robotics is slowly inching towards achieving human-level performance. We aimed to advance the process by creating a low-cost, low-maintenance, robust, and compact robotic hand with strong grip, dexterity, and controllability.”The developed robotic hand weighs less than 1.1 kg but still provides a fingertip force of 34 N (3.4 kilogram-force), and a strong grip force while handling up to an 18 kg payload. Their innovative design ensures 15 degrees of freedom across 20 joints and enough workspace for each finger. To evaluate the ILDA hand’s abilities, it was given tasks like crushing a soda can, holding an egg delicately, using tweezers, and cutting paper with scissors. The hand possessed high dexterity, along with tactile sensing (ability to detect physical interaction) capabilities, and precise control. The icing on the cake? This hand, which requires no additional modules, can easily be integrated into existing commercial robotic arms, making it versatile. “We hope that ILDA can be used to build prosthetic hands for people with disabilities,” says Prof. Kim. Indeed, they’ve ‘handled’ this quite well!ReferenceAuthors:Uikyum Kim 1,2,5, Dawoon Jung 3,5, Heeyoen Jeong4, Jongwoo Park 2, Hyun-Mok Jung2, Joono Cheong 3, Hyouk Ryeol Choi4, Hyunmin Do 2 & Chanhun Park 2Title of original paper:Integrated linkage-driven dexterous anthropomorphic robotic handJournal:Nature Communications DOI:10.1038/s41467-021-27261-0Affiliations:1 Department of Mechanical Engineering, Ajou University, Korea. 2 Department of Robotics and Mechatronics, Korea Institute of Machinery &Materials (KIMM), Korea. 3 Department of Control and Instrumentation Engineering, Korea University, Korea. 4 Department ofMechanical Engineering, Sungkyunkwan University,Korea. These authors contributed equally: Uikyum Kim, Dawoon Jung*Corresponding author’s email: ukim@ajou.ac.kr About Ajou UniversityFounded in 1973, Ajou University has quickly grown to become one of the top universities in the Republic of Korea. With over 15,000 students and 50 research centers in diverse fields, Ajou University partakes in the largest national research and graduate education project funded by the Korean Ministry of Education. In line with its recently reformed vision, Ajou University’s goal is to change society by connecting minds and carrying out high-impact research to improve the welfare of people in and outside Korea. Website: https://www.ajou.ac.kr/en/index.do About the authorDr. Uikyum Kim is an Assistant Professor with the Department of Mechanical Engineering at Ajou University. In 2017, Uikyum Kim received a Ph.D. in Mechanical Engineering from Sungkyunkwan University. Before coming to Ajou University, he was a senior researcher at the Robotics & Mechatronics lab of Korea Institute of Materials & Machinery. Currently, his group is developing interactive and dexterous robotic systems such as anthropomorphic robotic hands and teleoperated surgical robots. Kim’s group is also involved in designing various multi-axis force/tactile sensors for robotic applications and automated systems.

-

42

- 작성자국제교류팀

- 작성일2022-01-13

- 11334

- 동영상동영상